Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

In the highly competitive landscape of manufacturing, optimizing injection mold tooling is crucial for achieving maximum efficiency and reducing production costs. According to a recent report by the Plastics Industry Association, approximately 40% of manufacturing capital expenditures are allocated to mold tooling, emphasizing its significant role in the overall production process. Additionally, studies indicate that efficient tooling can enhance cycle times by up to 30%, directly impacting throughput and profitability. As companies strive to meet the growing demand for high-quality plastic components, understanding the intricacies of injection mold tooling becomes essential. This guide aims to provide essential tips and strategies for optimizing injection mold tooling, ensuring manufacturers can maximize their operational efficiency while maintaining product quality.

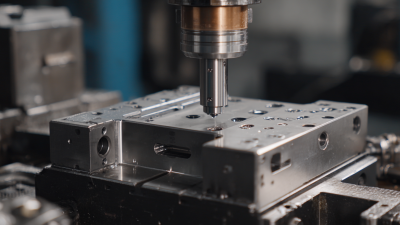

Identifying Key Factors in Injection Mold Tool Design for Optimal Performance

Optimizing injection mold tool design is crucial for achieving optimal performance in injection molding processes. Focus on identifying key factors that influence the efficiency and effectiveness of your tooling. One essential tip is to carefully select materials that withstand the specific conditions of the injection process, such as temperature and pressure. For instance, utilizing sensorized metal tools can enhance in-process monitoring of cooling performance, allowing for adjustments that reduce cycle time and improve part quality.

Another important aspect is the design of cooling channels. Implementing conformal cooling channel designs can dramatically improve heat transfer rates, leading to quicker cooling times and increased production efficiency. Additionally, a thorough analysis of your injection parameters, such as injection speed and packing pressure, can lead to better control over the final product's dimensions and mechanical properties. This approach not only minimizes defects but also enhances the overall durability and performance of the injection-molded components, ensuring that they meet the ever-evolving demands of various applications.

Techniques for Selecting the Right Materials to Enhance Mold Efficiency

When optimizing injection mold tooling, selecting the right materials is crucial for enhancing mold efficiency. The choice of materials influences not only the durability of the mold but also its thermal conductivity and processing characteristics. For instance, using high-quality steel or aluminum can significantly reduce wear and prolong the lifespan of the tooling. Additionally, materials with good thermal conductivity can improve the cooling cycle, leading to shorter production times and better part quality. Thus, careful consideration of material properties can result in substantial efficiency gains and cost savings in the long run.

Another factor to consider is the compatibility of the mold material with the injected resin. Each resin has specific processing temperatures and flow characteristics that can impact mold design and material selection. By understanding these relationships, one can select materials that complement the resin properties, minimize cycle times, and reduce the risk of defects. Advanced composites and specialty alloys may also be explored to meet specific requirements, such as resistance to corrosion or higher operating temperatures. Ultimately, diligent material selection tailored to the specific application can enhance mold performance and lead to improved overall productivity.

Best Practices for Maintenance and Repair of Injection Mold Tools

When it comes to maximizing the efficiency of injection mold tooling, maintenance and repair play a crucial role. Regular inspections are essential to identify wear and tear on mold components early. Implementing a schedule for routine maintenance can prevent unexpected breakdowns, which often lead to costly downtime. Key areas to focus on include checking for mold misalignment, monitoring cooling channels for blockages, and ensuring ejector pins are functioning correctly. By addressing these elements proactively, mold longevity and productivity can be significantly enhanced.

In addition to routine maintenance, understanding the best practices for repairs is vital. Utilizing high-quality materials and advanced techniques during repairs ensures that molds can withstand the rigorous demands of production. It is beneficial to maintain a detailed log of all maintenance activities and repairs performed. This documentation aids in tracking the mold’s performance over time, enabling operators to make informed decisions about when a tool should be replaced or refurbished. Educating team members on proper handling and care can also minimize risks associated with mold damage and extend the life cycle of the tooling.

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

| Maintenance Tip | Description | Frequency | Expected Outcome |

|---|---|---|---|

| Regular Cleaning | Clean molds after each production run to remove debris and residues. | After each run | Improved part quality and reduced defects. |

| Lubrication | Use appropriate lubricant on moving parts to prevent wear. | Monthly | Extended mold lifespan and smoother operation. |

| Inspection | Conduct regular inspections for cracks, wear, and alignment issues. | Weekly | Early identification of potential failures. |

| Cooling System Checks | Verify that cooling channels are clean and free of obstructions. | Before major production runs | Consistent temperature control and reduced cycle times. |

| Calibration | Regularly calibrate machines and tools to maintain precision. | Quarterly | Higher dimensional accuracy of molded parts. |

Understanding the Role of Cooling Systems in Tooling Efficiency Improvement

Cooling systems play a pivotal role in optimizing injection mold tooling by significantly enhancing efficiency in the manufacturing process. The speed at which a mold can produce parts is directly affected by its cooling capabilities. Effective cooling systems can reduce cycle times by ensuring that the material solidifies at a fast and uniform rate, which is crucial for maintaining dimensional accuracy and surface quality. By implementing advanced cooling techniques such as conformal cooling channels, manufacturers can improve heat distribution throughout the mold, leading to shorter cooling times and increased throughput.

Moreover, the design and placement of cooling channels are essential factors in achieving optimal cooling performance. Engineers should focus on strategic positioning that allows for uniform temperature control across the mold surface. This not only minimizes the risk of warping or defects in the molded parts but also prolongs the lifespan of the tooling itself. An investment in improved cooling solutions will pay off by enhancing overall productivity and reducing costs associated with scrap and rework, making it a critical aspect of modern injection mold tooling.

Implementing Advanced Technologies for Enhanced Injection Molding Processes

Implementing advanced technologies in injection molding processes can significantly enhance efficiency and product quality. One of the most impactful technologies is the integration of smart sensors and automation systems within the tooling. These systems provide real-time monitoring of various parameters such as temperature, pressure, and cycle times. By utilizing data analytics, manufacturers can predict potential issues before they arise, reducing downtime and minimizing waste. This proactive approach not only accelerates the production process but also ensures consistency in the quality of the final product.

Another crucial aspect is the adoption of advanced materials and design techniques, such as 3D printing for complex mold designs. This innovative approach allows for the rapid prototyping of molds, leading to shorter lead times and lower production costs. Moreover, the use of lightweight materials in tooling can enhance the overall efficiency of the injection molding process by allowing for faster cycles. As companies continue to embrace these technologies, they can achieve remarkable improvements in both operational efficiency and product performance, setting the stage for greater competitiveness in the market.

Related Posts

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

Challenges Faced in Injection Tooling Manufacturing Process

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

How to Choose the Right Die Cast Mold for Your Manufacturing Needs

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering