Unlocking Precision: The Science Behind Die Cast Tooling in Modern Manufacturing

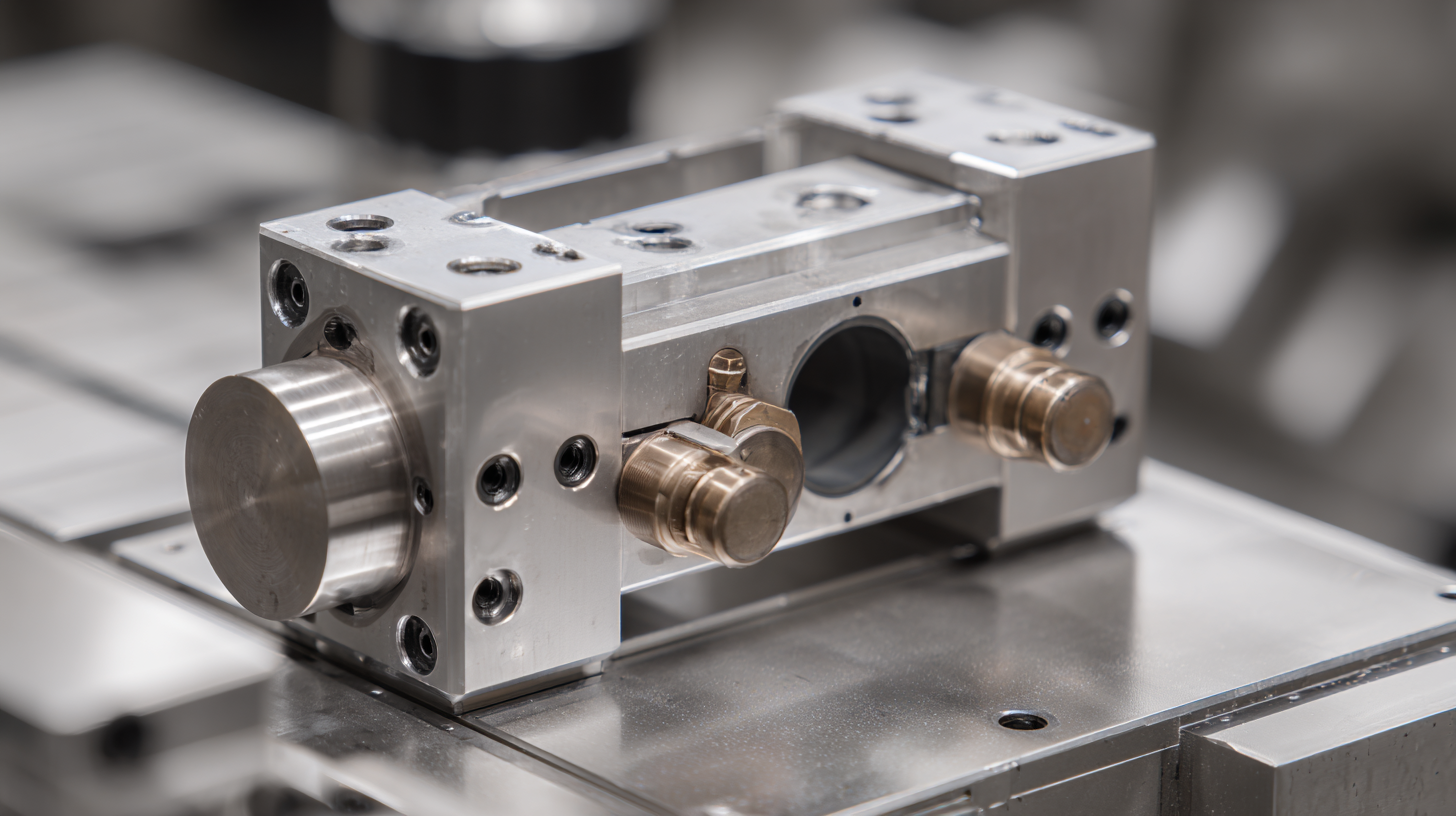

In the ever-evolving landscape of modern manufacturing, precision remains a paramount focus, particularly in the realm of die cast tooling. As industries strive to enhance efficiencies and reduce production costs, the integration of advanced technologies and methodologies becomes critical. This outline will delve into the intricacies of die cast tooling, exploring its foundational principles and the scientific advancements that unlock unprecedented levels of accuracy.

From innovative materials to cutting-edge machining techniques, we will investigate how die cast tooling not only streamlines production processes but also meets the stringent demands of quality and consistency that today’s manufacturers require. By examining case studies and expert insights, we aim to highlight the transformative impact that die cast tooling has on production capabilities, ultimately driving the future of manufacturing towards greater precision and efficiency.

The Evolution of Die Casting: From Traditional Methods to Modern Techniques

Die casting has undergone a remarkable transformation over the years, evolving from traditional methods into sophisticated modern techniques that enhance efficiency and precision. Historically, the process relied heavily on manual labor and rudimentary tools, which often led to inconsistencies in product quality. However, advancements in technology have paved the way for innovations such as Computer Numerical Control (CNC) machining and automated die casting systems. According to a recent industry report by Grand View Research, the die casting market is projected to reach USD 22.83 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.5%. This growth is attributed to the increasing demand for lightweight and high-strength components in sectors like automotive and aerospace.

To navigate the complexities of modern die casting, manufacturers are adopting sophisticated simulation software that allows for real-time adjustments during the production process. This technology ensures that the molds are optimized for minimal waste and maximum efficiency. Tips for improving die casting practices include investing in advanced tooling technologies and leveraging real-time analytics to enhance decision-making processes. Additionally, regular maintenance and updates for tooling equipment can significantly reduce downtime and improve overall production reliability.

As we look towards the future, the integration of sustainable practices is becoming essential. Die casting companies that focus on environmentally friendly materials and processes will not only comply with regulations but also strengthen their market positions. In this competitive landscape, staying updated with the latest innovations and methodologies is key to unlocking the full potential of die casting.

Unlocking Precision: The Evolution of Die Casting Techniques

This bar chart illustrates the evolution of die casting techniques from traditional methods to modern advancements over the past few decades. The data shows the percentage usage of various die casting techniques in manufacturing.

Key Benefits of Precision in Die Casting Tooling for Manufacturing Efficiency

In modern manufacturing, precision in die casting tooling is paramount for enhancing efficiency and performance. The integration of advanced digital manufacturing technologies has significantly optimized production processes across various industries, ensuring that die cast components meet the rigorous standards required today. This precision not only minimizes waste but also improves the quality of the end products, allowing manufacturers to stay competitive in a fast-paced market.

Die casting continues to drive innovation, especially in critical sectors like automotive and electronics. As market demands evolve, there is a clear trend towards higher quality molds and components, which are crucial for meeting increased performance expectations. The aluminum and zinc die casting markets are witnessing substantial growth, with projections indicating a robust expansion well into the next decade. This growth is spurred not only by consumer demand but also by advancements in tooling technology that facilitate greater accuracy and reliability in production. By focusing on these key benefits, manufacturers can achieve long-term sustainability and success in an increasingly challenging environment.

Material Selection in Die Casting: Choosing the Right Alloys for Optimal Results

Material selection plays a crucial role in the die casting process, directly influencing the quality and performance of the final product. Choosing the right alloys is essential to achieve optimal results, as different materials offer varying properties such as strength, corrosion resistance, and thermal conductivity. Aluminum, zinc, and magnesium alloys are among the most commonly used in modern die casting, each suited for specific applications based on their mechanical characteristics and cost-effectiveness. For instance, aluminum alloys provide excellent strength-to-weight ratio and corrosion resistance, making them ideal for automotive and aerospace components.

Moreover, the choice of alloy impacts not just the product's performance but also the manufacturing process itself. Certain materials require precise temperature control and may demand specialized tooling to achieve the desired surface finish and dimensional accuracy. Understanding the thermal and mechanical behaviors of these alloys allows manufacturers to optimize die casting parameters, ensuring efficient production and minimizing defects. By carefully selecting the right material, manufacturers can enhance the durability and reliability of their products while reducing waste and production costs.

Unlocking Precision: The Science Behind Die Cast Tooling in Modern Manufacturing

| Alloy Type | Melting Point (°C) | Density (g/cm³) | Tensile Strength (MPa) | Creep Resistance |

|---|---|---|---|---|

| Aluminum Alloy 380 | 540 | 2.7 | 250 | Excellent |

| Zinc Alloy die casting Zamak 3 | 390 | 6.3 | 260 | Good |

| Magnesium Alloy AZ91D | 590 | 1.81 | 220 | Fair |

| Copper Alloy | 1083 | 8.96 | 290 | Excellent |

The Role of Computer-Aided Design (CAD) in Enhancing Die Casting Accuracy

Computer-Aided Design (CAD) plays a pivotal role in enhancing the accuracy and efficiency of die casting processes. By allowing engineers to create detailed 3D models, CAD provides a platform to visualize the final product before any physical manufacturing begins. This early-stage simulation enables manufacturers to detect potential design flaws and material issues, thus preventing costly errors down the line. With advanced CAD software, adjustments can be made in real-time, facilitating a more agile design process that meets the precise specifications required for high-quality die casting.

Computer-Aided Design (CAD) plays a pivotal role in enhancing the accuracy and efficiency of die casting processes. By allowing engineers to create detailed 3D models, CAD provides a platform to visualize the final product before any physical manufacturing begins. This early-stage simulation enables manufacturers to detect potential design flaws and material issues, thus preventing costly errors down the line. With advanced CAD software, adjustments can be made in real-time, facilitating a more agile design process that meets the precise specifications required for high-quality die casting.

Moreover, CAD integrates seamlessly with computer numerical control (CNC) technology, streamlining the tooling design process. This integration leads to increased precision during machining, as machines can replicate the CAD designs with minimal human intervention. The ability to simulate the die-casting process through CAD further aids in optimizing worker efficiency and maximizing material usage. Ultimately, the adoption of CAD in die casting not only enhances accuracy but also accelerates production timelines, making it an indispensable tool in modern manufacturing practices.

Future Trends in Die Casting Technology: Innovations Shaping the Industry

The die casting industry is poised for significant growth, driven by advancements in technology and increasing applications in various sectors such as automotive, machinery manufacturing, and more. According to recent market analysis, the die casting market size is projected to experience a steady increase, with automotive applications commanding a substantial share. As manufacturers continue to seek more efficient and precise production methods, innovations in die casting technology are essential. With a focus on reducing production costs and enhancing product quality, new materials and techniques are reshaping the landscape of the industry.

Regions like China have been pivotal in this transformation. The machine tool market, closely aligned with die casting, is estimated to grow from approximately 631.36 billion yuan in 2019 to about 712.88 billion yuan in 2024, reflecting China's status as a leading producer and consumer of machine tools for 15 consecutive years. Events such as the 2026 Wuhan International Die Casting and Foundry Exhibition are expected to showcase global leaders and highlight innovations that are driving the industry forward. This convergence of technology and expertise is critical as traditional manufacturing paradigms shift towards more intelligent and automated solutions, revolutionizing the die casting sector.

Related Posts

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

How to Choose the Right Die Cast Process for Your Next Project

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering