Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

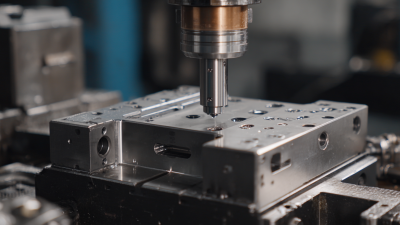

Plastic injection molding has emerged as a pivotal manufacturing process, accounting for over 30% of the global plastic production volume, according to industry reports by Grand View Research. This method, characterized by its ability to produce high-precision, complex shapes in a cost-effective manner, stands in stark contrast to other manufacturing processes like extrusion or blow molding. The versatility of plastic injection allows for the efficient creation of a vast array of products, from automotive components to consumer goods, meeting the diverse needs of various industries. As the demand for lightweight and durable materials continues to grow, understanding the distinctions between plastic injection and alternative manufacturing processes becomes essential for businesses looking to optimize production efficiency and reduce waste in an increasingly competitive market.

Comparison of Plastic Injection Molding with Blow Molding Techniques

When comparing plastic injection molding and blow molding techniques, it's essential to understand the fundamental distinctions in their processes and applications. Plastic injection molding involves injecting molten plastic into a pre-shaped mold, where it cools and solidifies, allowing for high precision and complex designs. This method is widely favored for creating parts that require tight tolerances and intricate details, making it ideal for industries such as automotive, consumer products, and electronics.

On the other hand, blow molding employs a different technique that involves inflating a heated plastic tube against the walls of a mold. This method is particularly suited for creating hollow objects, such as containers and bottles. While blow molding can produce larger and lighter components, it lacks the fine detail and precision that injection molding can achieve. Additionally, the capabilities of blow molding are generally limited to specific shapes, which can affect design flexibility. Understanding these differences helps manufacturers select the most suitable process for their specific product needs.

Understanding Rotational Molding and Its Applications in Manufacturing

Rotational molding, also known as rotomolding, is a versatile manufacturing process that allows for the creation of hollow plastic parts with uniform wall thickness. This method involves the use of a heated mold, which is filled with a powdered resin. As the mold rotates on two perpendicular axes, the powder melts and coats the interior surfaces, gradually forming a single, seamless piece. According to a report by Allied Market Research, the global rotational molding market is projected to reach $10.24 billion by 2025, growing at a CAGR of 4.2% from 2018 to 2025. This growth is driven by the increasing demand for custom and durable plastic products in various industries.

One of the distinguishing features of rotational molding is its ability to fabricate large, complex shapes that are difficult to achieve with traditional methods like injection molding. The process is particularly well-suited for creating large tanks, containers, and playground equipment, which often require sturdiness and design flexibility. Notably, a 2022 study revealed that 45% of manufacturers prefer rotational molding for creating intricate designs that would otherwise be impractical or cost-prohibitive. With its scalability and cost-effectiveness, rotational molding is positioned as a crucial technology in the evolving landscape of plastic manufacturing.

Examining 3D Printing as an Alternative to Traditional Molding Processes

3D printing has emerged as a significant alternative to traditional molding processes like plastic injection molding. According to a report from Wohlers Associates, the 3D printing market is expected to grow from $12 billion in 2020 to $35 billion by 2025, showcasing its increasing acceptance in various industries. Unlike injection molding, which requires significant upfront costs for creating molds, 3D printing operates on a layer-by-layer additive process, allowing for lower production costs and more customization options.

When considering 3D printing, it’s essential to understand its strengths. For short production runs or highly complex designs, 3D printing can dramatically reduce lead times and adapt designs quickly based on real-time feedback. Tips for enhancing your 3D printing experience include experimenting with different materials to find the optimal balance between cost and durability and continuously iterating your design to improve efficiency and functionality.

Despite its advantages, 3D printing still faces challenges such as slower production speeds for larger quantities. Awareness of these drawbacks is crucial as well. Always evaluate your project requirements and consider whether the speed of injection molding or the flexibility of 3D printing better suits your needs. Understanding both processes will enable you to make informed decisions that drive your manufacturing strategy forward.

Comparison of Manufacturing Processes

Pros and Cons of Vacuum Forming Compared to Injection Molding

When comparing vacuum forming to injection molding, it’s essential to analyze their unique advantages and disadvantages. Vacuum forming is often lauded for its lower start-up costs and simpler tooling requirements. According to a 2021 report by the Society of Plastics Engineers, tooling for vacuum forming can be up to 50% cheaper than that for injection molding, making it an attractive option for small production runs and prototypes. This process is ideal for creating large, shallow parts where detail is less critical, such as packaging and trays.

On the other hand, injection molding excels in producing complex shapes and tight tolerances. A study from the American Society of Mechanical Engineers indicates that injection molding can achieve precision within ±0.01 mm, making it the go-to method for high-volume manufacturing of intricate components. Additionally, while vacuum-formed parts tend to be less durable due to their material thickness limitations, injection molded products can use a wide range of thermoplastics, providing enhanced durability and strength. Thus, the choice between these two methods ultimately hinges on the specific application requirements and production volume considerations.

The Role of Compression Molding in Different Manufacturing Scenarios

Compression molding is a versatile manufacturing process that plays a significant role in various industrial applications. It involves placing a pre-measured amount of material into a heated mold, where it is then compressed to form a specific shape. This technique is particularly useful for creating large, thick components, and is often employed in industries such as automotive, aerospace, and consumer goods.

One of the key advantages of compression molding is its ability to accommodate a wide range of materials, including thermoplastics, thermosets, and elastomers. This flexibility allows manufacturers to choose the most suitable material for their product needs, enhancing overall performance and durability.

**Tips:** When considering compression molding for your project, start by evaluating your design and material requirements. Ensure you choose a mold design that minimizes flash and optimizes cycle times. Additionally, communicate closely with your manufacturer to develop a robust process that meets quality standards while keeping costs in check. This proactive approach can significantly improve the efficiency and outcome of your manufacturing process.

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes - The Role of Compression Molding in Different Manufacturing Scenarios

| Manufacturing Process | Material Compatibility | Production Speed | Cost Efficiency | Product Complexity | Typical Applications |

|---|---|---|---|---|---|

| Plastic Injection Molding | Thermoplastics, Thermosets | High Speed | High Volume, Moderate Cost | High Complexity | Automotive Parts, Consumer Goods |

| Compression Molding | Rubber, Thermosets | Moderate Speed | Cost Efficient for Large Parts | Moderate Complexity | Bumpers, Seals |

| Blow Molding | Polyethylene, PVC | High Speed | Cost Per Unit Increases with Size | Low Complexity | Bottles, Containers |

| Thermoforming | ABS, PET, Polypropylene | Moderate Speed | Moderate Cost, Efficient for Custom Shapes | Moderate Complexity | Packaging, Trays |

Related Posts

-

Challenges Faced in Injection Tooling Manufacturing Process

-

How to Choose the Right Die Cast Mold for Your Manufacturing Needs

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

10 Insights for Mastering Die Cast Plastic Techniques

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering