How to Master the Art of Plastic Casting for Innovative Product Design

The art of plastic casting has gained significant traction in innovative product design, driven by advancements in materials science and manufacturing technologies. According to a recent report by Grand View Research, the global plastic casting market is expected to reach $6.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1% from 2019 to 2025. This growth underscores the increasing demand for customized and efficient production methods in diverse industries, ranging from automotive to consumer electronics.

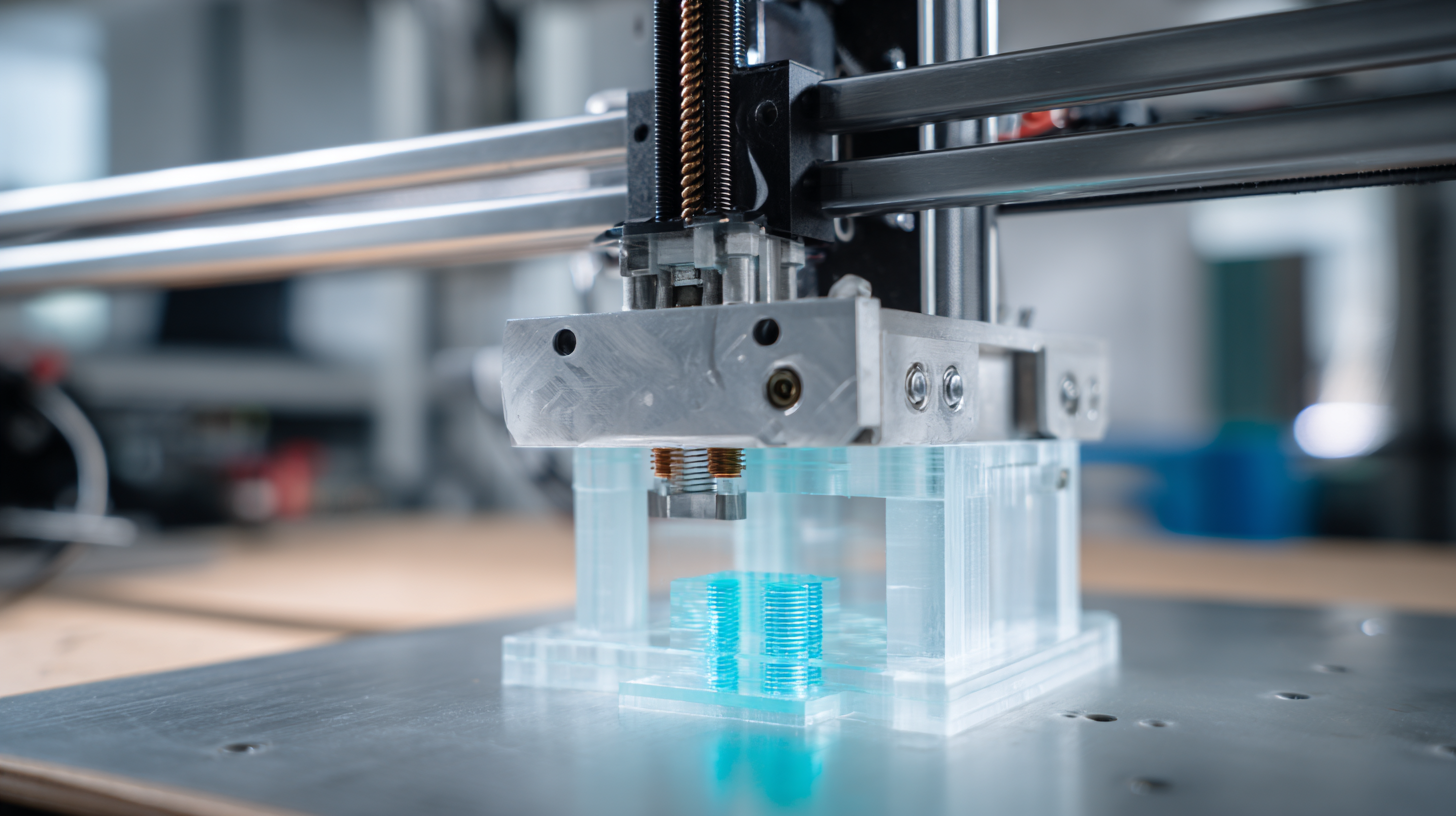

As designers and engineers seek to push the boundaries of creativity while maintaining cost-effectiveness, mastering plastic casting techniques becomes essential. Utilizing creative processes like injection molding and resin casting, professionals can achieve high precision and complex geometries that meet modern consumer needs. This guide aims to equip you with the skills and insights necessary to harness the full potential of plastic casting, facilitating the creation of groundbreaking products that resonate with market trends.

Understanding the Basics of Plastic Casting: Materials and Tools Needed

Plastic casting is a transformative technique widely used in product design, offering unique possibilities for innovation and creativity. To master this art, it is essential to understand the basic materials and tools required for effective plastic casting. Common materials include thermoplastics such as polyurethane and acrylic, known for their versatility and durability. These materials can be easily shaped and colored, making them ideal for producing intricate designs that can withstand varying conditions.

In addition to materials, having the right tools is crucial. A casting kit often comprises a molding container, mixing tools, and safety equipment. A vacuum chamber is also invaluable, as it minimizes air bubbles in the cast, leading to a smoother finish. Furthermore, a variety of pigments and fillers can be incorporated to enhance the aesthetic appeal and functionality of the final product. Mastering these basics lays the foundation for innovative product design, allowing creators to push the boundaries of conventional manufacturing techniques.

Plastic Casting Materials and Tools Comparison

This bar chart represents the average cost per kilogram for different plastic casting materials used in innovative product design. Understanding these costs helps designers choose materials based on budget and project requirements.

Step-by-Step Guide to Preparing Your Mold for Effective Casting Results

When preparing your mold for effective plastic casting, the first step is to choose the right materials. Selecting a mold-making substance such as silicone or urethane is crucial, as it will determine the mold's flexibility and durability. Ensure that the mold material is compatible with the type of plastic you plan to cast. Once you've chosen the material, create a master model of your design. This model needs to be meticulously crafted as it will directly influence the quality of the final product. The master should be smooth and free from any defects to ensure an accurate mold.

Next, the process of mold preparation involves applying a release agent to the model. This step is essential, as it helps prevent the casting material from sticking to the mold. After applying the release agent, carefully mix and pour the mold-making compound over the model, ensuring that no air bubbles are trapped. Allow the mold to cure completely before removal. Once you have your mold ready, you can proceed with the casting process, confident that your preparation work will yield high-quality and innovative product designs.

Techniques for Mixing and Pouring Plastic for Optimal Finish and Strength

When it comes to plastic casting, achieving an optimal finish and strength relies heavily on the techniques used for mixing and pouring the material. The first step involves selecting the right type of plastic resin that suits your product's specific requirements. Epoxy resins, for example, offer exceptional strength and durability, while polyurethane resins can be more flexible and versatile. It's crucial to read the mixing instructions carefully, as variations in ratios can drastically affect the final product's quality. Utilizing precise measuring tools ensures that you maintain the correct proportions, which is vital for achieving a consistent mixture.

When it comes to plastic casting, achieving an optimal finish and strength relies heavily on the techniques used for mixing and pouring the material. The first step involves selecting the right type of plastic resin that suits your product's specific requirements. Epoxy resins, for example, offer exceptional strength and durability, while polyurethane resins can be more flexible and versatile. It's crucial to read the mixing instructions carefully, as variations in ratios can drastically affect the final product's quality. Utilizing precise measuring tools ensures that you maintain the correct proportions, which is vital for achieving a consistent mixture.

Once mixed, the pouring technique plays a significant role in the final outcome. Pouring slowly and steadily at a low height helps to minimize bubbles and prevents disturbances in the mixture. Consider using a funnel or a spout to direct the flow precisely where it is needed. For larger molds, it's beneficial to pour the resin from one side, allowing it to flow naturally to fill the entire space, which can help in preventing air entrapment. Additionally, consider the environment—pouring in a controlled setting with stable temperatures can help maintain the integrity of the casting, leading to a smoother finish and enhanced strength in the finished product.

Troubleshooting Common Issues in Plastic Casting for Product Designers

When it comes to plastic casting, troubleshooting is an essential skill for product designers. Common issues such as air bubbles, uneven surfaces, and incomplete casts can arise, leading to compromised designs. To effectively address these problems, it's crucial to understand their root causes. For instance, air bubbles can result from improper mixing of materials or pouring too quickly. Designers should ensure thorough mixing and consider using a vacuum chamber to eliminate trapped air before curing.

Tips: Always pour the mixture slowly and from one side of the mold to reduce the chance of bubbles forming. Additionally, preheating the mold slightly can help improve the flow of the plastic, further minimizing imperfections.

Another frequent issue is warping or distortion of the final product, which usually stems from inadequate cooling. Allowing the cast to cool slowly and uniformly can help maintain its intended shape. Using molds made from materials that conduct heat evenly can also aid in achieving a consistent cooling process.

Tips: Keep the environment at a stable temperature during the cooling phase and avoid any sudden temperature changes that could lead to thermal shock and warping. Engaging in these troubleshooting strategies can greatly enhance the quality of plastic casting in product design.

Innovative Applications of Plastic Casting in Modern Product Development

Plastic casting has surged in popularity within modern product development due to its versatility and efficiency. According to a report by MarketsandMarkets, the global plastic market is expected to reach $650 billion by 2025, with a significant portion driven by innovative casting techniques. This method allows designers to create complex shapes and forms that would be challenging or cost-prohibitive with traditional manufacturing methods. For instance, companies can produce lightweight components that enhance product performance while reducing material consumption.

Moreover, the application of plastic casting extends beyond standard products, influencing sectors such as automotive and consumer electronics. In automotive design, a report from Grand View Research indicates that using plastic parts can reduce vehicle weight by up to 20%, leading to increased fuel efficiency. Additionally, in the consumer electronics sector, brands are employing plastic casting to create aesthetically pleasing yet functional device housings, resulting in enhanced user experience and lower production costs. Innovative casting techniques enable designers to push the boundaries of creativity, resulting in products that stand out in a competitive market and align with sustainability goals.

Related Posts

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

How to Optimize Your Die Mold Production Process for Maximum Efficiency

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering