5 Tips on Enhancing Tool and Die Precision with 20 Percent Increased Efficiency

In the dynamic world of manufacturing, achieving precision in tool and die production is paramount, as even the slightest error can lead to significant operational inefficiencies and increased costs. According to a recent report by the Precision Metalforming Association, enhancing die precision can improve production efficiency by up to 20%, showcasing the critical importance of effective measurement and calibration techniques.

Given that tool and die account for approximately 60% of direct manufacturing costs, investing in methods to enhance their precision not only optimizes the manufacturing workflow but also elevates overall product quality. This blog aims to provide actionable tips on how to elevate tool and die precision while simultaneously achieving substantial efficiency gains, ensuring that your operations remain competitive in an increasingly demanding market.

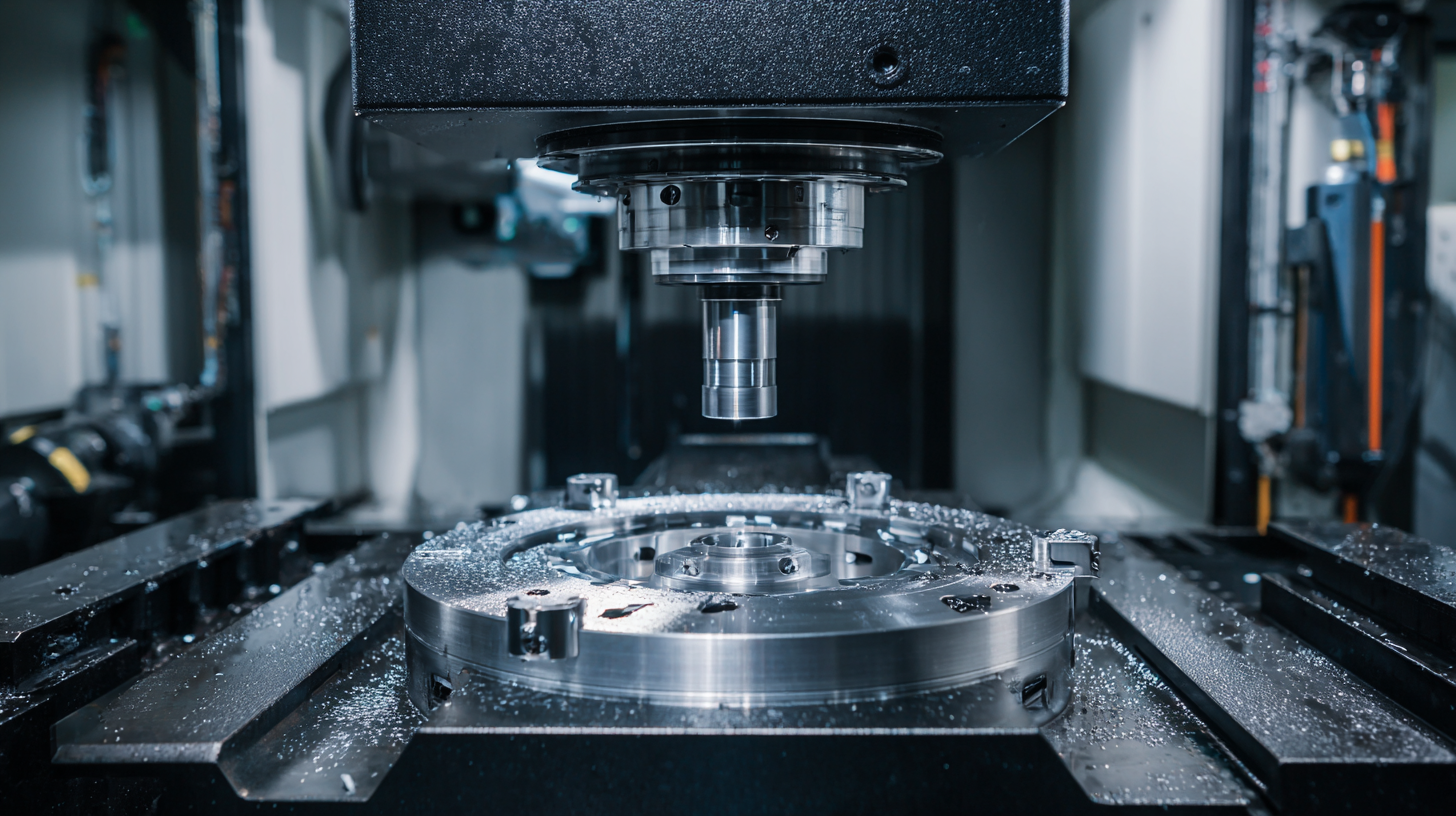

Understanding the Importance of Precision in Tool and Die Manufacturing

In the realm of tool and die manufacturing, precision is of utmost importance. The smallest deviations can lead to significant defects in the final products, resulting in costly rework and wasted materials. Therefore, enhancing precision not only improves product quality but also boosts overall efficiency in the manufacturing process. This means that manufacturers must adopt practices that prioritize accurate measurements and tolerances consistently.

One effective tip for improving precision is to implement advanced measurement technologies. Utilizing tools such as laser measurement systems or coordinate measuring machines (CMM) allows for real-time adjustments and verifications during production. Additionally, regular training and upskilling of the workforce can lead to a more knowledgeable team that understands the nuances of precision engineering.

Another key strategy is optimizing the machining processes. By analyzing workflows and identifying bottlenecks, manufacturers can streamline operations to eliminate errors. This can involve investing in high-quality cutting tools and maintaining them to ensure they operate at peak performance. Thus, by focusing on both technology and personnel, manufacturers can achieve better precision, resulting in enhanced overall efficiency.

Implementing Advanced Measurement Techniques for Increased Accuracy

Advanced measurement techniques are essential for enhancing the precision of tool and die manufacturing. One effective approach is implementing laser measurement systems, which provide highly accurate data and reduce human error. By utilizing laser scanning, manufacturers can capture intricate details of tool geometry, ensuring that every component meets stringent specifications. This precision not only leads to improved product quality but also supports a more efficient production line.

Another valuable technique is the use of coordinate measuring machines (CMM). CMMs enable operators to measure physical geometrical characteristics by sensing discrete points on the surface of an object with a probe. By incorporating advanced CMM software, manufacturers can analyze complex shapes and tolerances with greater ease, minimizing the risk of defects. Additionally, regular calibration and maintenance of these machines are crucial to maintain their accuracy and reliability, further boosting efficiency in the production process.

Lastly, leveraging digital twins in the manufacturing process can significantly enhance precision. By creating a virtual representation of tools and dies, manufacturers can simulate various machining processes and predict potential errors before they occur. This proactive approach allows for immediate adjustments, ensuring higher accuracy and efficiency. Integrating these measurement techniques not only elevates the quality of tool and die work but also leads to notable efficiency gains within the manufacturing workflow.

Enhancing Tool and Die Precision with Advanced Measurement Techniques

This chart illustrates the improvement in precision and efficiency before and after the implementation of advanced measurement techniques in tool and die manufacturing. The data indicates a marked decrease in precision levels and a significant increase in efficiency, highlighting the effectiveness of adopting new measurement strategies.

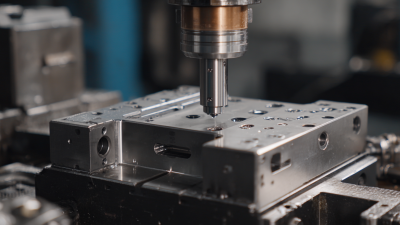

Streamlining Workflows to Maximize Efficiency in Tool Production

Streamlining workflows in tool production is essential to maximizing efficiency and precision in the manufacturing process. According to a report by the National Tooling and Machining Association (NTMA), companies that implemented lean manufacturing practices have seen productivity improvements of up to 30%. This increase can be attributed to a systematic elimination of waste and a focus on continuous improvement, allowing manufacturers to produce high-quality tools and dies with reduced lead times.

Investing in advanced technologies such as Computer Numerical Control (CNC) machines and automated inspection equipment can further enhance production workflows. A study published by the International Journal of Advanced Manufacturing Technology found that CNC machining can improve accuracy by 50% compared to traditional methods, while also reducing the need for manual adjustments. By adopting such technologies, manufacturers can achieve a 20% increase in production efficiency, enabling them to meet market demands more effectively and gain a competitive edge.

Moreover, optimizing team collaboration through integrated software systems can help streamline communication and project management. Research indicates that companies leveraging collaborative tools experience a 25% reduction in project completion times. By fostering a culture of cooperation and utilizing technology, tool and die manufacturers can not only enhance precision but also adapt more swiftly to changing customer requirements, thus driving overall efficiency in their operations.

Incorporating Technology Solutions for Enhanced Tool Performance

In today's highly competitive manufacturing landscape, enhancing tool and die precision while increasing efficiency is paramount. One effective way to achieve this is by incorporating advanced technology solutions. Leveraging AI, Natural Language Processing (NLP), and data analytics can drive innovation and streamline processes, providing manufacturers with the tools needed for superior performance.

Tip #1: Implement AI-driven analytics to identify performance bottlenecks. By analyzing operational data, businesses can pinpoint areas that require improvement, ensuring that machines operate at peak efficiency.

Tip #2: Adopt personalized adaptive learning tools for your workforce. These technologies can enhance employee training, making it more relevant and impactful, which ultimately leads to improved tool handling and precision in operations.

Tip #3: Stay updated with the latest advancements in quantum computing, as these emerging technologies have the potential to revolutionize manufacturing processes, enabling higher precision and reduced lead times. Embracing these tech solutions will not only enhance tool performance but also position your business ahead of the curve.

Continuous Training and Skill Development for Precision Improvement

Continuous training and skill development are crucial for enhancing precision in the tool and die industry. According to a report by the National Institute for Metalworking Skills, companies that invest in the training of their workforce can see up to a 20% improvement in efficiency. As tools and dies become increasingly complex, the need for specialized skills that ensure accuracy in production processes cannot be overstated. For example, advanced CNC machining techniques require operators to have a deeper understanding of programming and operation to maintain tight tolerances, which can directly impact product quality.

Furthermore, a survey from the Precision Metalforming Association indicates that organizations prioritizing skill development often experience lower defect rates, which can be attributed to higher competency levels in workers. Continuous education in the latest technologies and methodologies not only boosts individual performance but also enhances overall team productivity. Implementing structured training programs helps workers stay updated on industry standards and innovations, positioning companies to meet rising customer demands efficiently and accurately. This focused approach towards skill enhancement plays a pivotal role in driving precision improvements across the industry.

Related Posts

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Challenges Faced in Injection Tooling Manufacturing Process

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

10 Insights for Mastering Die Cast Plastic Techniques

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering